ADDITIONAL INFORMATION

According to customer requirements, the production of national standard, American standard, German standard, Japanese standard, non-standard high, medium and low pressure various specifications of carbon steel, stainless steel, alloy steel flange, elbow, Bend, reducing pipe, tee, four, head, pipe cap and thread, socket series pipe components products.

ADDITIONAL INFORMATION

According to customer requirements, the production of national standard, American standard, German standard, Japanese standard, non-standard high, medium and low pressure various specifications of carbon steel, stainless steel, alloy steel flange, elbow, Bend, reducing pipe, tee, four, head, pipe cap and thread, socket series pipe components products.

Description

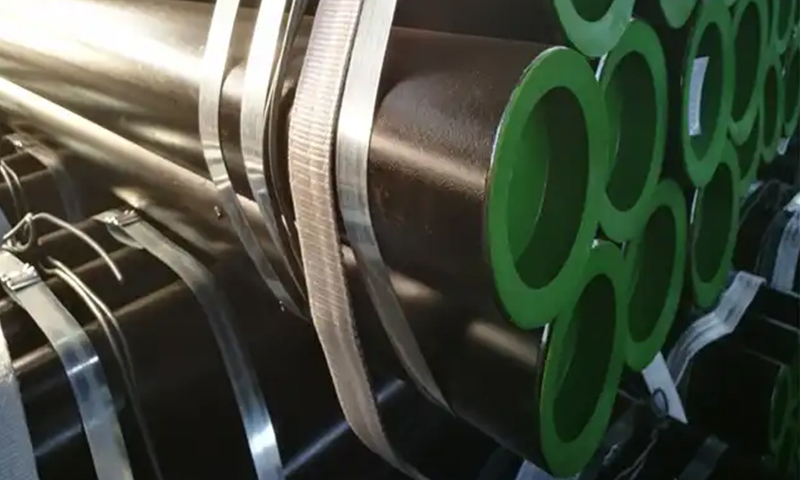

Seamless Pipeline, Seamless Line Pipe

Standard: API 5L

Application: For gas, water, transportation in Petroleum and natural gas industries

Tolerance on Dimensions

|

Standard |

Out Diameter | Wall Thickness | |

| API 5L | Tolerance | Tolerance | |

| D<60.3 | +0.41mm, -0.80mm | +15.0%, -12.5% | |

| D≥60.3 | +0.75%D, -0.75%D | +15.0%, -12.5% | |

Standard

| Standard | Grade | Chemical Components (%) | Mechanical Properties | ||||||

| C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | |||

| API 5L PSL1 | A | 0.22 | – | 0.90 | 0.030 | 0.030 | ≥331 | ≥207 | |

| B | 0.28 | – | 1.20 | 0.030 | 0.030 | ≥414 | ≥241 | ||

| X42 | 0.28 | – | 1.30 | 0.030 | 0.030 | ≥414 | ≥290 | ||

| X46 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥434 | ≥317 | ||

| X52 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥455 | ≥359 | ||

| X56 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥490 | ≥386 | ||

| X60 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥517 | ≥448 | ||

| X65 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥531 | ≥448 | ||

| X70 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥565 | ≥483 | ||

| API 5L PSL2 | B | 0.24 | – | 1.20 | 0.025 | 0.015 | ≥414 | ≥241 | |

| X42 | 0.24 | – | 1.30 | 0.025 | 0.015 | ≥414 | ≥290 | ||

| X46 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥434 | ≥317 | ||

| X52 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥455 | ≥359 | ||

| X56 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥490 | ≥386 | ||

| X60 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥517 | ≥414 | ||

| X65 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥531 | ≥448 | ||

| X70 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥565 | ≥483 | ||

| X80 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥621 | ≥552 | ||

Packing and transportation:

Description

Seamless Pipeline, Seamless Line Pipe

Standard: API 5L

Application: For gas, water, transportation in Petroleum and natural gas industries

Tolerance on Dimensions

|

Standard |

Out Diameter | Wall Thickness | |

| API 5L | Tolerance | Tolerance | |

| D<60.3 | +0.41mm, -0.80mm | +15.0%, -12.5% | |

| D≥60.3 | +0.75%D, -0.75%D | +15.0%, -12.5% | |

Standard

| Standard | Grade | Chemical Components (%) | Mechanical Properties | ||||||

| C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | |||

| API 5L PSL1 | A | 0.22 | – | 0.90 | 0.030 | 0.030 | ≥331 | ≥207 | |

| B | 0.28 | – | 1.20 | 0.030 | 0.030 | ≥414 | ≥241 | ||

| X42 | 0.28 | – | 1.30 | 0.030 | 0.030 | ≥414 | ≥290 | ||

| X46 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥434 | ≥317 | ||

| X52 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥455 | ≥359 | ||

| X56 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥490 | ≥386 | ||

| X60 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥517 | ≥448 | ||

| X65 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥531 | ≥448 | ||

| X70 | 0.28 | – | 1.40 | 0.030 | 0.030 | ≥565 | ≥483 | ||

| API 5L PSL2 | B | 0.24 | – | 1.20 | 0.025 | 0.015 | ≥414 | ≥241 | |

| X42 | 0.24 | – | 1.30 | 0.025 | 0.015 | ≥414 | ≥290 | ||

| X46 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥434 | ≥317 | ||

| X52 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥455 | ≥359 | ||

| X56 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥490 | ≥386 | ||

| X60 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥517 | ≥414 | ||

| X65 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥531 | ≥448 | ||

| X70 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥565 | ≥483 | ||

| X80 | 0.24 | – | 1.40 | 0.025 | 0.015 | ≥621 | ≥552 | ||

Packing and transportation:

Reviews

There are no reviews yet.

Reviews

There are no reviews yet.