ADDITIONAL INFORMATION

According to customer requirements, the production of national standard, American standard, German standard, Japanese standard, non-standard high, medium and low pressure various specifications of carbon steel, stainless steel, alloy steel flange, elbow, Bend, reducing pipe, tee, four, head, pipe cap and thread, socket series pipe components products.

ADDITIONAL INFORMATION

According to customer requirements, the production of national standard, American standard, German standard, Japanese standard, non-standard high, medium and low pressure various specifications of carbon steel, stainless steel, alloy steel flange, elbow, Bend, reducing pipe, tee, four, head, pipe cap and thread, socket series pipe components products.

Description

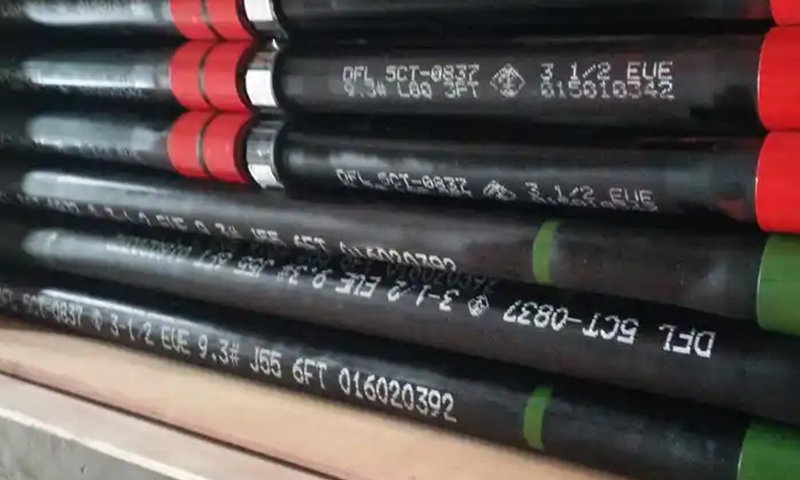

API Tubing Pup Joints

Manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Optional diameters, lengths, weights, and grades are available upon request.

| Diameters: | .75″ through 4.5″ nominal O.D. |

| Weights: | Standard or Heavy Wall |

| Lengths: | 2, 3, 4, 6, 8, 10, 12 ft. Standard (Lengths up to 20′ available upon request) |

| Grades: | J-55, N-80, N-80 Q & T, L-80, P-110, 13-CR and other premium grades |

| Connections: | EUE, NUE, Buttress |

Premium Tubing Pup Joints

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

| Diameters: | .75″ through 4.5″ nominal O.D. |

| Weights: | Standard or Heavy Wall |

| Lengths: | 2, 3, 4, 6, 8, 10, 12 ft. Standard |

| Grades: | J-55, N-80, N-80 Q & T, L-80, P-110 and specialty grades |

| Connections: | Premium threads available include TenarisHydril, Kawasaki, and VAM |

Casing Pup Joints

Any length, weight, and grade are available upon request.

| Diameters: | 4.5″ through 20″ nominal O.D. |

| Weights: | Standard or Heavy Wall |

| Lengths: | Custom lengths available from 2 ft. through 20 ft. |

| Connections: | STC, LTC, Buttress and premium threads |

Perforated Pup Joints

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

| Diameters: | 3.4″ through 4.5″ nominal O.D. |

| Weights: | Standard or Heavy Wall |

| Lengths: | As required |

| Grades: | J-55, N-80, N-80 Q & T, L-80, P-110 and specialty grades |

| Connections: | EUE, NUE, Buttress, Premium and T & C |

Manufacturing process of pup ioint

Upsetting

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

Hydro Testing

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

Full Body Ultrasonic Inspection

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

Profiling

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

Special End Area Inspecting

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

Heat Treat

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

Packing and transportation:

Description

API Tubing Pup Joints

Manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Optional diameters, lengths, weights, and grades are available upon request.

| Diameters: | .75″ through 4.5″ nominal O.D. |

| Weights: | Standard or Heavy Wall |

| Lengths: | 2, 3, 4, 6, 8, 10, 12 ft. Standard (Lengths up to 20′ available upon request) |

| Grades: | J-55, N-80, N-80 Q & T, L-80, P-110, 13-CR and other premium grades |

| Connections: | EUE, NUE, Buttress |

Premium Tubing Pup Joints

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

| Diameters: | .75″ through 4.5″ nominal O.D. |

| Weights: | Standard or Heavy Wall |

| Lengths: | 2, 3, 4, 6, 8, 10, 12 ft. Standard |

| Grades: | J-55, N-80, N-80 Q & T, L-80, P-110 and specialty grades |

| Connections: | Premium threads available include TenarisHydril, Kawasaki, and VAM |

Casing Pup Joints

Any length, weight, and grade are available upon request.

| Diameters: | 4.5″ through 20″ nominal O.D. |

| Weights: | Standard or Heavy Wall |

| Lengths: | Custom lengths available from 2 ft. through 20 ft. |

| Connections: | STC, LTC, Buttress and premium threads |

Perforated Pup Joints

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

| Diameters: | 3.4″ through 4.5″ nominal O.D. |

| Weights: | Standard or Heavy Wall |

| Lengths: | As required |

| Grades: | J-55, N-80, N-80 Q & T, L-80, P-110 and specialty grades |

| Connections: | EUE, NUE, Buttress, Premium and T & C |

Manufacturing process of pup ioint

Upsetting

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

Hydro Testing

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

Full Body Ultrasonic Inspection

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

Profiling

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

Special End Area Inspecting

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

Heat Treat

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

Packing and transportation:

Reviews

There are no reviews yet.

Reviews

There are no reviews yet.